Antwort Is Kaizen a tool or methodology? Weitere Antworten – Is Kaizen a methodology

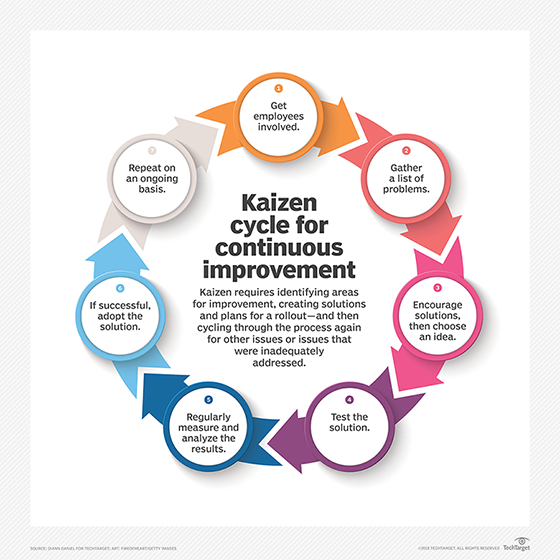

Kaizen methodology is an approach that pushes forward the continuous improvement in an organization, based on the constant small positive changes that can result in major and more significant growth.Kaizen tools provide businesses with the means to fine-tune their operations. No matter if you are involved in manufacturing or the service sector, these tools are your essential partners for success in today's fast-paced business world.In the 21st century, business consultants in various countries have engaged in widespread adoption and sharing of the kaizen framework as a way to help their clients restructure and refocus their business processes.

What are the principles of Kaizen methodology : The Core of KAIZEN™

There are 5 Fundamental KAIZEN™ Principles that are embedded in every KAIZEN™ tool and every KAIZEN™ behavior. The 5 principles are: Know your Customer, Let it Flow, Go to Gemba, Empower People and Be Transparent.

Is Kaizen an agile methodology

Derived from the Japanese term for continuous improvement, Kaizen, the agile software development methodology, encapsulates a key principle of Japanese management. Its purpose is to help companies address challenges by identifying areas where commitments fall short and stimulating team brainstorming for enhancements.

Is Kaizen a lean tool or Six Sigma : Kaizen in relation to Lean Six Sigma

In both cases, this is about the reduction of squandering and variation. Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization.

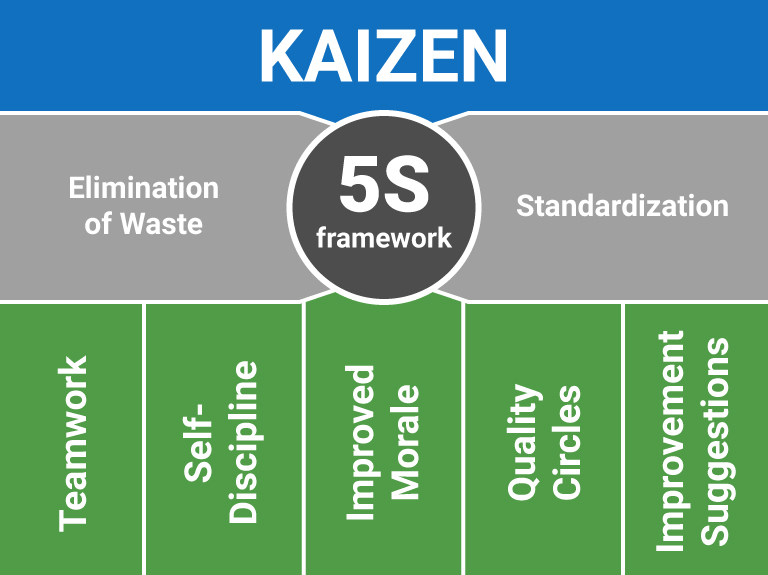

5S is derived from the philosophy of "kaizen", which simply means "continuous improvement". Japanese automotive manufacturer, Toyota, states that the philosophy of "kaizen" is one of its core values. This philosophy is supported by three key principles, one of which is 5S.

The 5S methodology in Kaizen is based on the initial letters of five Japanese words: Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). This approach was originally developed to improve efficiency by organizing operations and workspaces.

Is Kaizen part of Scrum

A Kaizen (Japanese for "good change") is the result of the Sprint Retrospective. It is collaboratively identified within the event by the entire Scrum team to solve the team's most important problem or help the team continuously evolve.Derived from the Japanese term for continuous improvement, Kaizen, the agile software development methodology, encapsulates a key principle of Japanese management. Its purpose is to help companies address challenges by identifying areas where commitments fall short and stimulating team brainstorming for enhancements.In spite of differences in methodology, focus and scale of operation in both the concept, it can be simply concluded that Kaizen is one of the Technique of the T QM for continuous improvement of quality, process and performance of the organization.

5S is a five-step methodology that, when followed, creates a more organized and productive workspace. In English, the 5S's are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes. What Is the 5S Methodology

Is 5S a methodology : Method and Implementation Approach. 5S is a cyclical methodology: sort, set in order, shine, standardize, sustain the cycle. This results in continuous improvement.

How is Kaizen different from lean methodology : Kaizen focuses on eliminating waste, improving productivity, and achieving sustained continual improvement in targeted activities and processes of an organization. Lean production is founded on the idea of kaizen – or continual improvement.

Is kanban a Kaizen tool

The kaizen philosophy is a way of thinking. And there are many tools and methods that support its implementation in life and in business. One such methodology is Kanban. So when a business implements Kanban, it also employs the kaizen principle of continuous improvement.

Kaizen in relation to Lean Six Sigma

In both cases, this is about the reduction of squandering and variation. Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization.Derived from the Japanese term for continuous improvement, Kaizen, the agile software development methodology, encapsulates a key principle of Japanese management. Its purpose is to help companies address challenges by identifying areas where commitments fall short and stimulating team brainstorming for enhancements.

Is 5S methodology different from kaizen : While 5S and Kaizen are two distinct philosophies, they are closely related. 5S provides a foundation for Kaizen by creating a workplace environment that is conducive to continuous improvement. Kaizen, in turn, helps to sustain 5S gains by ensuring that the workplace remains organized and efficient over time.