Antwort Is Kaizen useful in 5S? Weitere Antworten – Is Kaizen part of 5S

5S is derived from the philosophy of "kaizen", which simply means "continuous improvement". Japanese automotive manufacturer, Toyota, states that the philosophy of "kaizen" is one of its core values. This philosophy is supported by three key principles, one of which is 5S.Both are focused on Improving Efficiency

Kaizen accomplishes this by identifying different processes that take place and making improvements to them. 5S works by looking for waste and messes and having them eliminated.Implementing 5S Kaizen leads to a reduction of lost or damaged items in a workplace. A clean, organized workstation with properly labeled tools enables employees to decide on what needs to be replaced and repaired in their designated places; this minimizes the number of damaged, misplaced or lost tools.

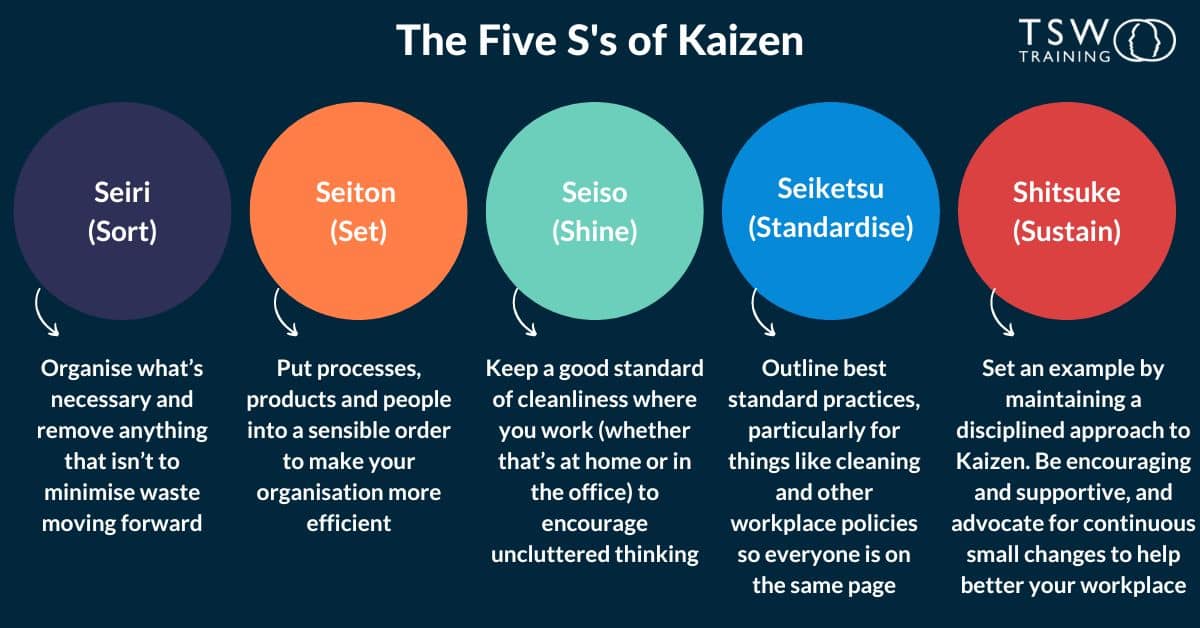

What is 5S and Kaizen activities : In English, the 5S's are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

What is the difference between 5S and Kaizen

While Kaizen is a general approach to improvement, 5S is a way to lay the groundwork for improvement. The two go hand in hand with 5S being part of the Kaizen system and lean manufacturing.

What is the 5S Kaizen format : By implementing a lean 5S system – sort, set in order, shine, standardize, sustain – organizations can create a clean, well ordered, and disciplined work environment. Many companies implement only the first three steps, hoping the last two will automatically follow.

5S is a workplace organization methodology that focuses on creating a clean, organized, and efficient work environment. Kaizen is a continuous improvement philosophy that emphasizes making small, incremental changes to improve processes and products over time.

If your organization values gradual improvements and employee engagement in the improvement process, Kaizen might be the better choice. Six Sigma uses statistical data to analyze business processes and aims for perfection, or zero defects.

How is Kaizen useful

Kaizen is about decreasing waste by eliminating overproduction, improving quality, being more efficient, having less idle time, and reducing unnecessary activities. All these translate to cost savings, and can turn potential losses into profits.5S focuses on eliminating waste and inefficiencies in the workplace. This methodology can be applied to every department and action that takes place. On the other hand, Six Sigma is a process improvement strategy that eliminates defects by implementing standard processes, identifying problem areas, and more.Lean Six Sigma tends to standardize more than Kaizen, but the spirit of Kaizen still believes in the organization. Kaizen believes in improving organizational processes. Six Sigma's unification allows for the process to be targeted, which increases only a specific component of the entire product.

While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety. 6 S lean not only helps organizations promote efficient working environments but also establishes a sustainable culture of safety.

Is Kaizen useful : Kaizen is important because it is a process used to identify key problems at their source. Kaizen can't just be a one-person job, as every employee needs to be active in making small improvements on a frequent basis.

Is Kaizen outdated : “Its principles guide effective implementation of changes and ensure long-term success and resilience across various industries.” There are a number of aspects in which Kaizen remains relevant for organizations in 2024, agrees Dara Kiernan, process improvement consultant at KPI Consulting.

What are the negatives of Kaizen

Kaizen disadvantages

- Companies with cultures of territorialism and closed communication may first need to focus on cultural changes to create a receptive environment.

- Short-term Kaizen events may create a burst of excitement that is shallow and short-lived and, therefore, is not sustained.

With Kaizen's focus on culture, 5S's on environment, Lean on waste and Six Sigma on defects and quality, we have a powerful combination of tools poised to transform organizations. What if Kaizen, Lean, 5S and Six Sigma are applied from time of booking a surgical case to hospital discharge and/or rehab5S is a workplace organization methodology that focuses on creating a clean, organized, and efficient work environment. Kaizen is a continuous improvement philosophy that emphasizes making small, incremental changes to improve processes and products over time.

Why Kaizen failed : Kaizen events often fail due to overly broad scopes, lacking clear and specific objectives, which hinders effective problem-solving. It's crucial to scope Kaizen events properly, ensuring they focus on specific issues to facilitate meaningful improvements.