Antwort What is 5S in 6 sigma? Weitere Antworten – What is 5S in Six Sigma

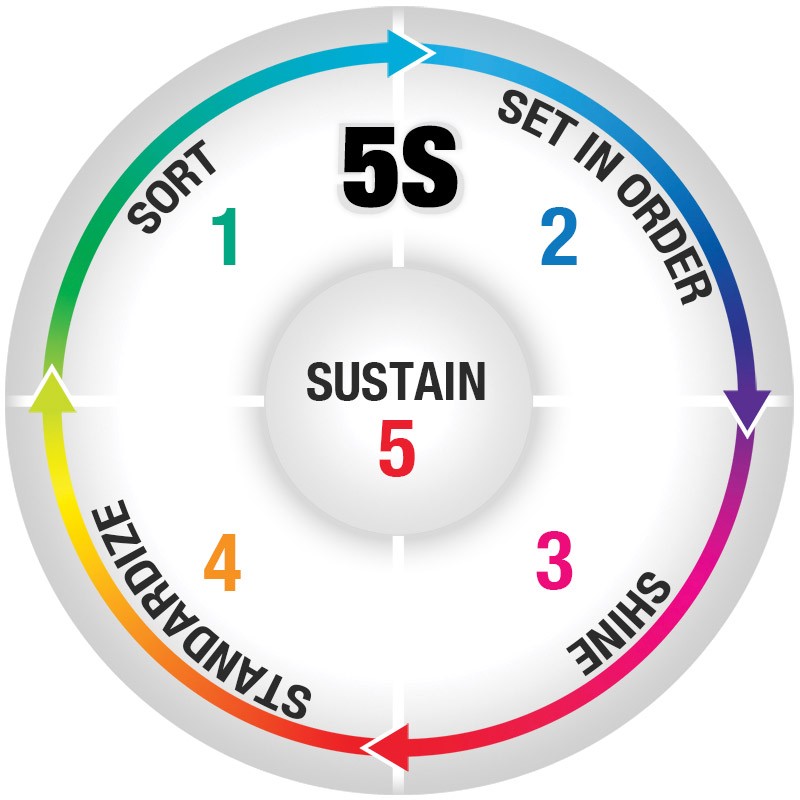

The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.5S Training Course Overview

5S is an organisational method describing how to organise a workspace. It is one of the most widely adopted techniques from lean manufacturing toolbox. The main objective of 5S is to create a clean, orderly environment where there is a place for everything and everything is in its place.5S is a five-step methodology that, when followed, creates a more organized and productive workspace. In English, the 5S's are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

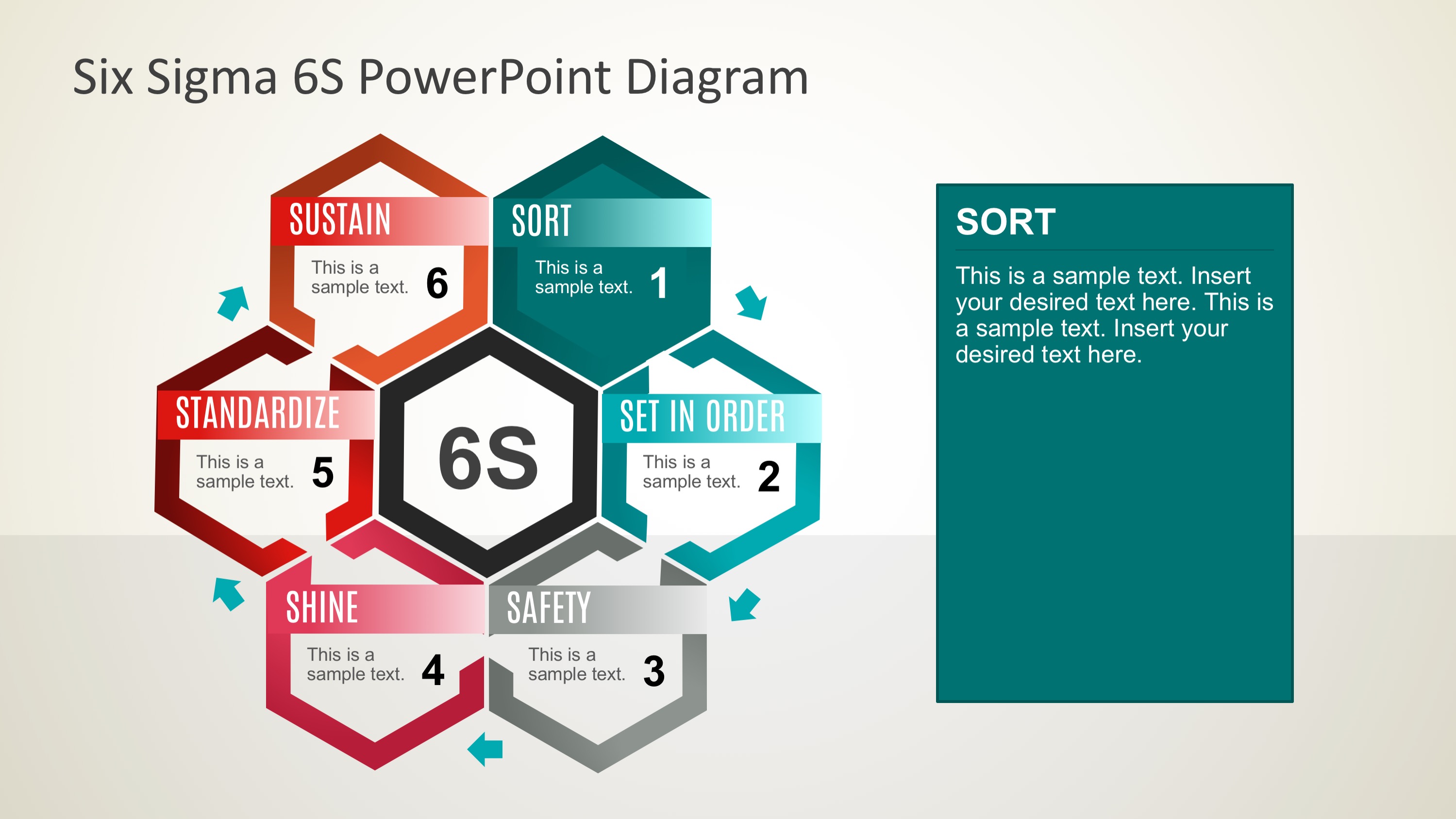

What is the difference between 5S and 6S Six Sigma : The main difference between the two is a single 'S' which stands for Safety. Therefore, a 6S audit is basically a 5S one with extra attention to safety. 6S audits include safety as a vital element of running an efficient business but that doesn't mean that 5S doesn't account for safety at all.

What is 5S with example

5s Lean is a systematic approach aimed at optimizing workplace operations by reducing waste, improving efficiency, and creating an organized environment. The methodology derives its name from its core principles: Sort, Set in Order, Shine, Standardize, and Sustain.

What is Six Sigma 5 steps : The Core Six Sigma Process Steps (DMAIC)

The Six Sigma Methodology comprises five data-driven stages — Define, Measure, Analyze, Improve and Control (DMAIC).

The 5S methodology, rooted in the philosophy of Kaizen, provides a structured approach to workplace organisation and continuous improvement. Organisations can create organised, efficient, and safe work environments by implementing Sort, Set in Order, Shine, Standardise, and Sustain.

5s Lean is a systematic approach aimed at optimizing workplace operations by reducing waste, improving efficiency, and creating an organized environment. The methodology derives its name from its core principles: Sort, Set in Order, Shine, Standardize, and Sustain.

What are the 5S of kaizen

Edwards Deming, Kaizen emphasizes making incremental improvements in quality, efficiency, and waste reduction. The 5S methodology, an integral part of Kaizen, consists of Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety. 6 S lean not only helps organizations promote efficient working environments but also establishes a sustainable culture of safety.The more number of standard deviations between process average and acceptable process limits fits, the less likely that the process performs beyond the acceptable process limits, and it causes a defect. This is the reason why a 6σ (Six Sigma) process performs better than 1σ, 2σ, 3σ, 4σ, 5σ processes.

Edwards Deming, Kaizen emphasizes making incremental improvements in quality, efficiency, and waste reduction. The 5S methodology, an integral part of Kaizen, consists of Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

What is 5S in one word : They are sort, set, shine, standardize and sustain. Lean bases the words on the original Japanese: seiri, seiton, seiso, seiketsu and shitsuke. 5S is a key component in eliminating the eight wastes of Lean when setting up a workstation.

What are the 5 elements of Six Sigma : The Six Sigma Methodology

DMAIC is a data-driven method used to improve existing products or services for better customer satisfaction. It is the acronym for the five phases: D – Define, M – Measure, A – Analyse, I – Improve, C – Control. DMAIC is applied in the manufacturing of a product or delivery of a service.

What is sigma 5 rule

Essentially, the Five Sigma Rule states that if you have a normally distributed dataset, then almost all values in that dataset will fall within five standard deviations of the mean. This means that only 0.00006% of values will fall outside of this range.

7S Lean Methodology which could be applied by any scope organizations is derived from. five Japanese lean 5s methodology; Sort, set in order, Shine, standardise and sustain, extended by Safety as. well as Spirit in the recent years. This Methodology aids organisation in work environment for effectiveness.continuous improvement

Kaizen is a Japanese term meaning change for the better or continuous improvement. It is a Japanese business philosophy that concerns the processes that continuously improve operations and involve all employees. Kaizen sees improvement in productivity as a gradual and methodical process.

What are 5 phases 5S : The five words in 5S represent the five steps to accomplish this goal. They are sort, set, shine, standardize and sustain. Lean bases the words on the original Japanese: seiri, seiton, seiso, seiketsu and shitsuke.