Antwort Why companies don t use Six Sigma? Weitere Antworten – Why has Six Sigma not been successful in all companies

They lack the skills required to implement it.

Many people who work in manufacturing industries may have heard of Six Sigma, but they do not know much about it. This means that they will not be able to implement it properly. You need to hire skilled professionals who have experience in implementing Six Sigma.Many of the most cutting-edge companies, such as Microsoft and Pfizer, still use Six Sigma and Lean Six Sigma to enhance their processes, reduce errors, and optimize performance. On this page: Brief Historical Overview of Six Sigma. The Core Principles and Techniques of Six Sigma.Lack of resources.

Getting sufficient numbers of “belts” trained at whatever levels is a major investment, not only in actual cash for the training, but in terms of time and adding extra work to busy managers' lives. Is it seen as too complicated In some quarters, Six Sigma is regarded as too complicated.

What are the negatives to Six Sigma : Criticism 4: Poor measurement system for Six Sigma may erode employee motivation. Also, Six Sigma creates a culture of command, and culture associated which may stifle the employee creativity and innovation. The efficiency programs like Six Sigma are designed to identify problems in work processes.

What company failed in Six Sigma

Motorola became the founder of Six Sigma in 1986, aiming to lessen defects and enhance exceptional in its merchandise. However, Motorola failed to sustain its aggressive benefit and marketplace percentage, because it focused too much on efficiency and is now not sufficient on innovation and client desires.

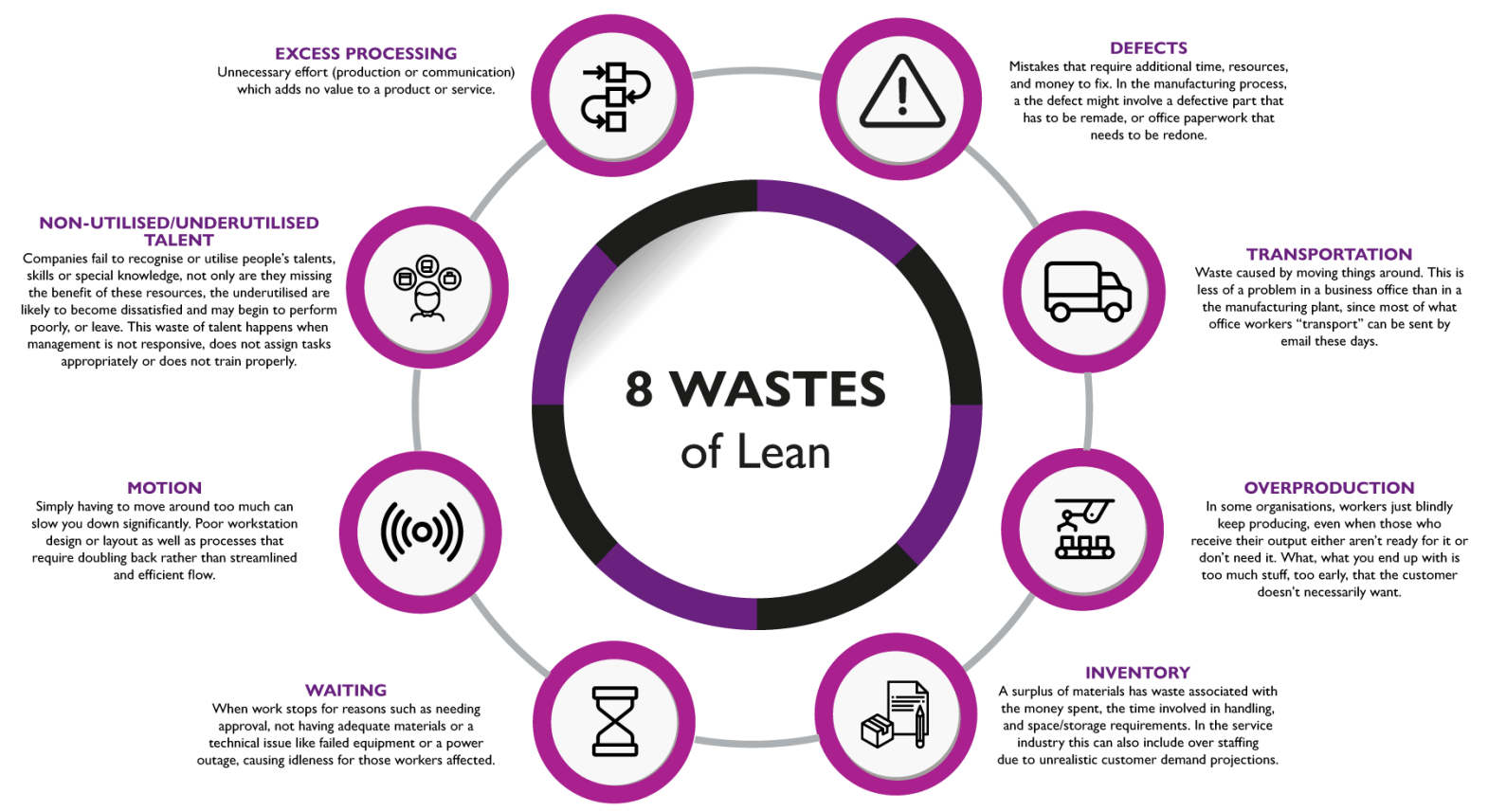

What are the problems with Six Sigma : 10 Common Challenges in Implementing Lean Six Sigma and How to Overcome Them

- Resistance to Change:

- Lack of Leadership Support:

- Inadequate Training and Resources:

- Difficulty in Data Collection and Analysis:

- Lack of a Continuous Improvement Culture:

- Ineffective Project Selection:

- Failure to Measure Results:

- Scope Creep:

Relying on obsolete standards, stifling innovation and a cult-like devotion to consultants and bureaucracy are among the major criticisms leveled at this venerable approach to quality management.

Yes, Six Sigma remains highly relevant in 2024, adapting to current market demands with a focus on digital transformation, sustainability, and quality improvement across various industries.

Why is Six Sigma wrong

Process data is often flawed or wrong.

Six sigma data analysis requires good data, which I have found is often lacking for the process(es) being improved. It is better to use Lean methodologies to understand and standardize the process first.First Reason: With Six Sigma, Motorola and GE focused too much on the efficiency of internal processes but didn't on the customer needs and innovation. It led to a focus on cost-cutting and efficiency at the expense of innovation.Variance is the enemy of Six Sigma. When a production process lacks the stability to consistently create high-quality output, it will continue producing defective products until professionals intervene and improve the process.

What are the limitations of Six Sigma One of the challenges of the fact-driven process of identifying a problem and working toward a solution is that it tends to leave out a key component: humans—and more importantly, how humans impact and work through different obstacles.

Does boeing use Six Sigma : Boeing Commercial Airplanes launched Six Sigma in 1999, and developed their own training the following year.

What has replaced Lean Six Sigma : Today, agile methodology stands out as the most popular process improvement approach, and Six Sigma comes second, despite its decreasing trend.

Will AI replace Six Sigma

The Love Story Unfolds

Now, you might be wondering, "Are AI and automation here to replace Lean Six Sigma" Far from it! In fact, they're more like the dynamic duo, working in tandem to take our methodologies to new heights.

Our Six Sigma programs include: Classroom Training: programs taught by Master Black Belts with real world experience.Lean Six-Sigma is a method that transforms the ability of organizations to improve quality, customer satisfaction, reduce costs and increase production efficiency. With this guided and structured method, based on data, many companies have improved their production processes, Nike is one of them.

Has Six Sigma been replaced : Many manufacturing businesses continue to use the basic Six Sigma framework while enhancing it with more modern approaches and applications, such as Lean and sustainability.